- Home

-

Product

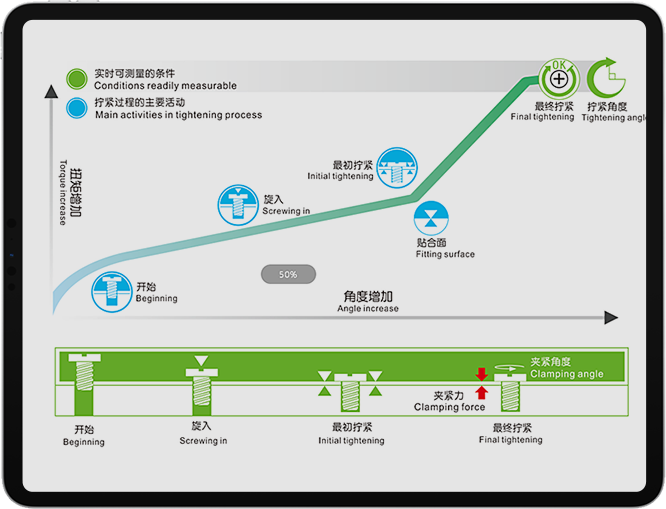

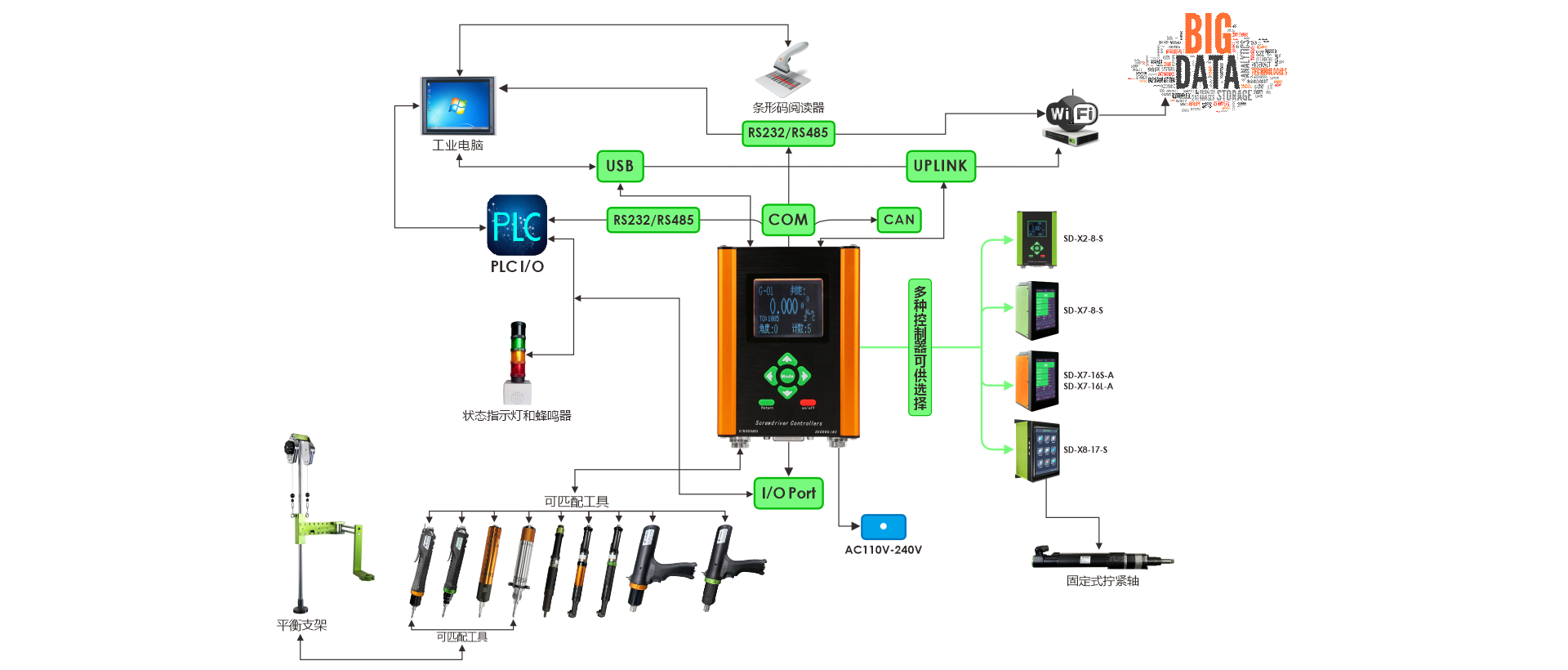

Intelligent Servo Transducer controlled Tightening Tool Intelligent Servo Current Controlled Torque Tightening Tool Intelligent Servo Lithium Battery Tightening Tool Intelligent Servo Electric Screwdriver Controller Intelligent Electric Screwdriver Measuring Instrument Fixed Tightening spindle Special Tightening Head Intelligent Servo Automation Tightening Solution Multi Functional Industrial Computer Series Fastener Positioning Error Prevention System Optional FunctionIntelligent Servo Torque Trangducer Hand Press Type Intelligent Servo Torque Trangducer Gun Wrench Intelligent Servo Torque Trangducer Angle WrenchIntelligent Servo Current Control Hand Press Type Intelligent Servo Current Controlled Torque Gun Wrench Intelligent Servo Current Controlled Torque Wrench Intelligent Servo Current Controlled Automation type

- Solution

- Support

- News

- About