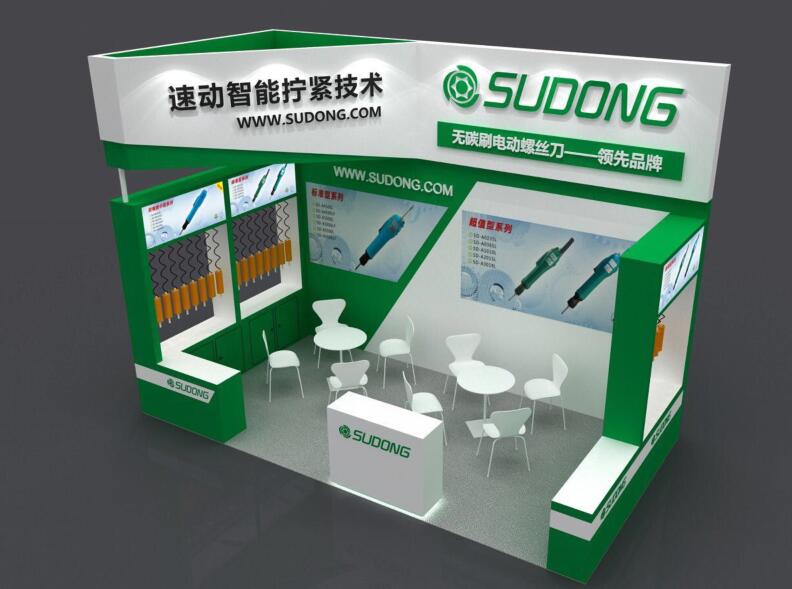

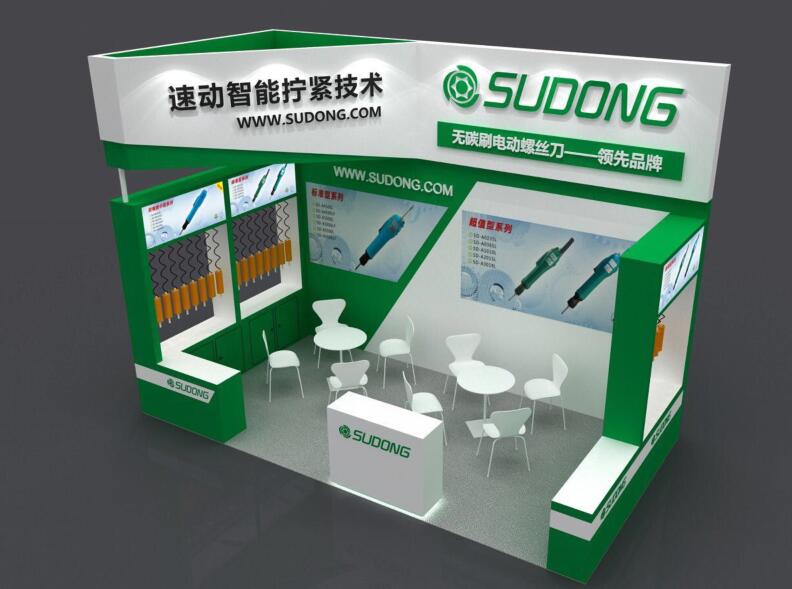

Quick booth number: E1-G08

Time: July 3-6, 2019

Location: Shanghai New International Expo Center

With the development of future automobiles, new car manufacturers and new modes of transportation are disrupting the automotive industry, and technologies such as electrification, intelligence, sharing, and networking are emerging. The 15th AMTS 2019 Shanghai International Automotive Manufacturing Technology and Equipment and Materials Exhibition closely follows industry development and market demand, and pays more attention to the future automotive development sector - focusing on high-tech such as intelligent networking, lightweight body structures, AR/VR, informatization, and digital production. Through a one-stop display of innovative technologies and applications in the engineering field of automotive body stamping, welding and connection, painting, overall vehicle assembly, parts machining, assembly and testing, vehicle materials and design, development and trial production, intelligent production line logistics, quality control and testing.

Speedy Electronics will also participate in the exhibition on time. Speedy SUDONG has been focusing on the fastening and industrial processing fields for 9 years, valuing technological innovation and possessing multiple independent intellectual property rights. Its products are precise and durable. Speedy SUDONG will establish sales and service institutions in multiple cities in China, including South China, North China, East China, Southeast, and Northwest, to provide continuous and stable service guarantees for consumers.

Host organization:

The 15th AMTS 2019 Shanghai International Automotive Manufacturing Technology and Equipment and Materials Exhibition will be hosted by Lijin Exhibition (Shanghai) Co., Ltd. Lijin Exhibition is a joint venture established by Lijin Expo Group, a subsidiary of RELX Group, and Shanghai Hengjin Exhibition Co., Ltd. It is also a member company of Lijin Expo Group. Li Jin Exhibition will leverage the sales network of Li Zhan Expo Group in 40 countries to attract more international enterprises and buyers to participate.

Sudong is deeply rooted in China, looking at the world, and every effort and effort comes from a beautiful vision: to become a world-class fastener product and a globally recognized product. Exhibition area: 100000 square meters, expected to gather 800 exhibitors from around the world, attracting 80000 professional visitors.

List of Quick Moving Exhibits:

Product features:

1. The quick action brushless servo electric screwdriver can achieve free programming of the tightening assembly process. Within the performance parameter range, it is possible to freely set and adjust torque, speed, waiting time, and rotation direction according to different tightening process requirements, achieving precise tightening.

2. The quick action brushless servo electric screwdriver is based on servo control technology, which can ensure that the torque accuracy of millions of tightening assemblies is controlled within a standard deviation of ≤ 3%.

3. The use of brushless servo motors significantly reduces operating costs, resulting in a long service life while ensuring robust power performance and torque output, making it an ideal CNC tightening assembly process choice for customers.

Under normal working conditions, the quick acting brushless servo electric screwdriver can achieve a Cmk ≥ 1.67 (torque setting tolerance ± 10% in accordance with IS05393 and 6 Sigma principle). The Cmk value of 1.67 means that there is only a 0.6 error rate per million screws, which is as high as 99.9994% pass rate.

5. The quick action brushless servo electric screwdriver adopts a brushless motor, combined with SD-PF5015 or SD-PF5030 controllers, to ensure the flexibility and reliability of the tightening process.

6. The built-in current and angle measurement can achieve precise control and monitoring of the quick acting brushless servo electric screwdriver during various tightening processes, record all important tightening process parameters, and ensure the highest accuracy.

7. The high-speed brushless servo electric screwdriver has high-precision and comprehensive monitoring functions, which can ensure the reliability of the tightening process to the greatest extent.

Exhibition Hall Overview:

W5 Hall: Equipment maintenance and upgrading and renovation; Component cleaning engineering; Quality control and testing engineering;

W4 Hall: Component Manufacturing Engineering; Laser engineering;

W3 Hall: Welding and Connection Engineering

W2 Hall: Welding and assembly engineering; Painting engineering; Stamping engineering+automotive mold design and manufacturing

W1 Hall: Product development (battery | motor | electronic control | vehicle networking | autonomous driving)+synchronous engineering; Materials and lightweight; TechShow Zone+vehicle development+design, trial production, development, and testing

E3 Hall: Component Assembly System Integration+Powertrain Assembly System Integration+Robot System Integration

E2 Hall: Assembly Technology and Automation Technology;

Hall E1: Final assembly project+intelligent production line logistics; Assembly technology and automation technology;

Welcome all distinguished guests to attend on time, SUDONG intelligent tightening technology welcomes you!