On August 13th, the 3-day SIAF2020 Guangzhou International Industrial Automation Technology and Equipment Exhibition came to a successful conclusion. As a leading event in the intelligent manufacturing and industrial automation solutions industry, the successful conclusion of this exhibition will undoubtedly leave a strong mark on the construction of intelligent manufacturing and smart factory 4.0. As a leader in the tightening industry, Quick Action Intelligent Tightening also gained a lot from this exhibition.

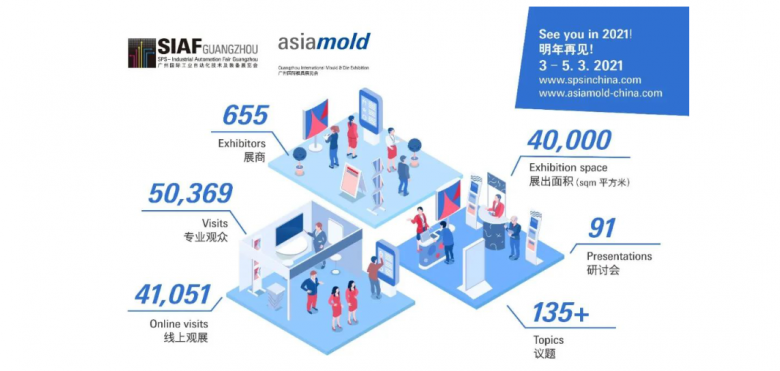

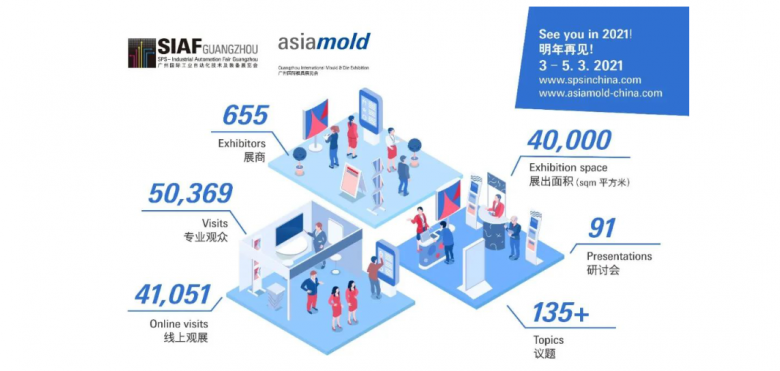

As a leading hub for intelligent industrial automation solutions in South China, SIAF's exhibition revolves around six main themes, including electrical systems, industrial robots and machine vision, sensing technology and industrial measurement, connectivity technology and intelligent warehousing, logistics integration solutions, smart factories, and exhibits and technologies for the Internet of Things. The latest manufacturing solutions and products are showcased in five exhibition halls covering an area of 40000 square meters. We have attracted 655 exhibitors from all over the world and over 50000 professional visitors to participate in the grand event.

This exhibition focuses on two key words, namely "intelligent manufacturing" and "industrial automation". With the promotion and implementation of the Internet of Things, artificial intelligence, cloud computing, big data, and 5G applications, the traditional simple and repetitive process model of factories is no longer sufficient for the efficient development of the times. The automation of various production processes in factories and the integration of new technologies in products and solutions are bound to trigger a new round of industrial transformation. So, how will the automation of tightening processes and the intelligence of tightening tools, which play an important role in factory automation production, be upgraded and transformed? In this exhibition, the best answer was given by Quick Action Intelligent Tightening.

During the three-day exhibition, Speedy Intelligent Tightening attracted a group of exhibitors to stop and inquire with its industry-leading, highly intelligent, and automated tightening products and surrounding supporting equipment, as well as thoughtful brand services, and eye-catching booth design. It also won recognition and praise from many industry insiders.

At this exhibition, the star product of Quick Action - the carbon free brush intelligent electric screwdriver torque tester and surrounding supporting products - made a brilliant debut and received much attention. In order to comply with the trend of intelligent manufacturing and industrial automation, Quick Action, which has been deeply rooted in the tightening industry for more than ten years, has always been at the forefront of industry development. In order to solve the problems of low technical content and low level of automation in tightening tools, and to break the situation of simple, repetitive, labor-intensive, and low accuracy in the tightening industry, QuickAction relies on its strong R&D and production capabilities to focus on research and development. Its carbon free intelligent electric screwdriver has high accuracy, and the torque accuracy of millions of tightening assemblies is accurately controlled within the standard deviation of ≤ 3%, within the performance parameter range, Capable of freely setting and adjusting torque, speed, waiting time, and rotation direction according to different tightening process requirements, achieving precise tightening. High degree of automation, unique data traceability function, precise control of brushless servo electric screwdriver in various tightening processes can be achieved through built-in current and angle sensors, and all important tightening process parameters can be recorded in real time. The data acquisition system on its computer side makes the entire tightening process more intuitive, while also storing tightening data and calculating work qualification rates, improving data traceability.

The fast acting carbon free brush intelligent electric screwdriver, which combines high precision, high automation, comprehensive data tracing and digitization, not only showcased the cutting-edge development achievements of the industry at the exhibition, pointing out the direction of automation development in the tightening industry, but also showcased its skills in the automated production lines of various factories. The era of automation industry has arrived, and rapid intelligent tightening will continue to make efforts, adhere to scientific research and innovation, strive for excellence, and bring the most cutting-edge and suitable tightening services to more customers. With our own efforts, we will help accelerate the implementation of "intelligent manufacturing"!