On May 27-30, the 22nd Lijia International Intelligent Equipment Exhibition will be grandly held at the Chongqing International Expo Center. The exhibition will be themed "Hui", with a total of 8 themed exhibition areas and an exhibition area of 70000 square meters. 700 domestic and foreign enterprises will participate, and more than 30000 professional visitors from the central and western regions are expected to visit and purchase.

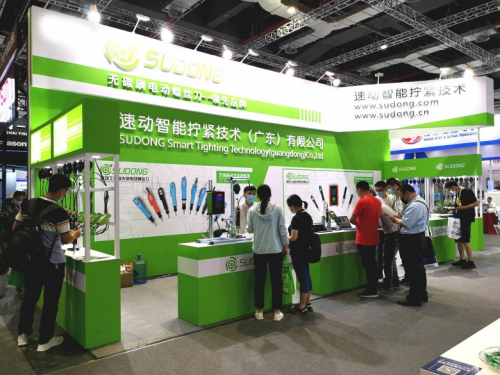

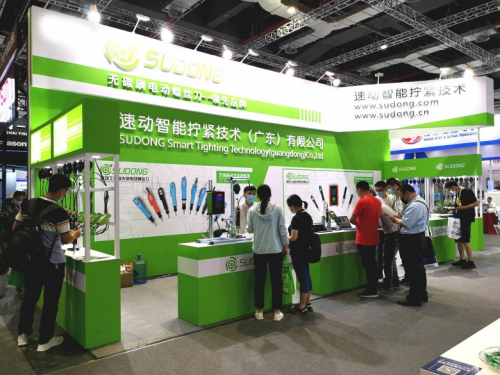

As a well-known domestic supplier of industrial intelligent tightening equipment, Sudong Intelligent has been invited to participate in the exhibition and will make a stunning appearance at booth 6355 of S6 Hall, showcasing to industry insiders the new technologies, products, and concepts independently developed by enterprises in recent years, such as intelligence, automation, and digitization.

Founded in 2007, Speedy Intelligent Tightening Technology Co., Ltd. has always kept its original intention in mind and strived to move forward. It mainly involves the production, manufacturing, and sales of carbon free electric screwdrivers, torque testers, and peripheral supporting products. It always adheres to the combination of independent research and technological innovation, constantly breaks down industry technical barriers, and breaks the long-term monopoly of foreign tightening brands. It has created a Chinese brand of "tightening tools" through digitization Intelligence and integration continue to lead China's industry towards the world.

The high-quality development of the manufacturing industry is the top priority of high-quality economic development. Building a socialist modernized strong country and developing and strengthening the real economy cannot be separated from the manufacturing industry. This exhibition focuses on intelligent manufacturing equipment and technology, showcasing new achievements in the equipment manufacturing industry in recent years, involving advanced products and technologies in fields such as intelligent manufacturing, automation, and digital factories, as well as complete factory automation production solutions. The upgrading of intelligent industries has become an irreversible trend.

As a key carrier of electronic manufacturing enterprises, electric screwdrivers are undergoing a new round of intelligent upgrading, playing an increasingly important role in the industrial manufacturing field, especially in the automotive manufacturing industry. In this context, products such as the Speedy Intelligent SUDONG Brushless Servo Intelligent Torque Sensor Series and Brushless Clutch Fixed Torque Series have gained deep love from market users in fields such as automotive tightening shafts, new energy, and rail transit due to their excellent performance.

Quick action brushless clutch fixed torque series

Quick action brushless clutch fixed torque series products, with built-in contactless switch, no need to replace consumables, have an ultra long service life; Integrating new intelligent counting, effectively controlling the yield rate; The torque output of the brushless motor is stable, easy to operate, and the screwdriver time is long; Infrared intelligent fixtures and LED warning lights allow users to visually determine the locking condition of screws, providing an excellent industrial grade tightening tool for electronics industry professionals.

Quick action brushless servo intelligent torque sensor series

The brushless servo intelligent torque sensor series products can achieve free programming of the tightening assembly process. Within the performance parameter range, it is possible to freely set and adjust torque, speed, waiting time, and rotation direction according to different tightening process requirements, achieving precise tightening.

Through the built-in torque sensor and angle sensor, precise control of each tightening process can be achieved, and all important tightening process parameters can be recorded in real time. Based on servo control technology, it can ensure that the torque accuracy of millions of tightening assemblies is controlled within the standard deviation of ± 3%. The built-in current and angle measurement can achieve precise control and monitoring of various tightening processes, record all important tightening process parameters, and ensure the highest accuracy.

Under normal working conditions, the brushless servo intelligent torque sensor can achieve Cmk ≥ 1.67 (torque setting tolerance ± 10%), in accordance with ISO 5393 and 6Sigma principles. A Cmk value of 1.67 means that there is only a 0.6 error rate per million screws, which is a high pass rate of 99.9994%. At the same time, brushless motors are used in conjunction with SD-PF5015 or SD-PF5030 controllers to ensure the flexibility and reliability of the tightening process, helping manufacturing enterprises achieve true precision and intelligence.

Under the premise of foreign technology blockade and domestic talent shortage, China's industrial intelligence road still has a long way to go. However, due to the strong support of the country and the enthusiastic expectations of countless Chinese people, more patriotic enterprises have emerged who are not afraid of difficulties and are dedicated to developing intelligent equipment, creating a bright and new future for China's industrial intelligence. Quick Action Intelligence expects to use the small product of intelligent electric screwdrivers to help promote a significant transformation from "Made in China" to "Made in China".