What are the differences between intelligent servo electric screwdriver and ordinary electric screwdriver? Many customers have such doubts, but in fact, only the locking screw is used. Generally, electric and pneumatic batches are still widely used in industry. The main reason is low cost, light weight, and fast effectiveness. However, with the gradual transformation of China's manufacturing industry and the continuous updating of products, the existing general electrical and pneumatic batches can no longer adapt to the development of high-end manufacturing.

In this environment, new locking screw technologies have emerged, especially for the tightening requirements of high-end manufacturing precision. It can be said that the use of servo control technology for precision screw tightening is a very good technology. Now let's talk about the differences between the quick acting intelligent servo batch and the ordinary electric batch!

1、 Speed

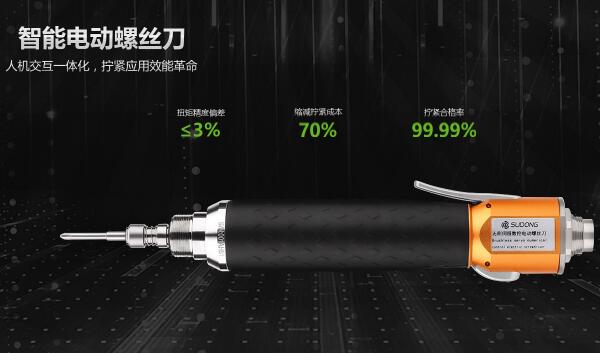

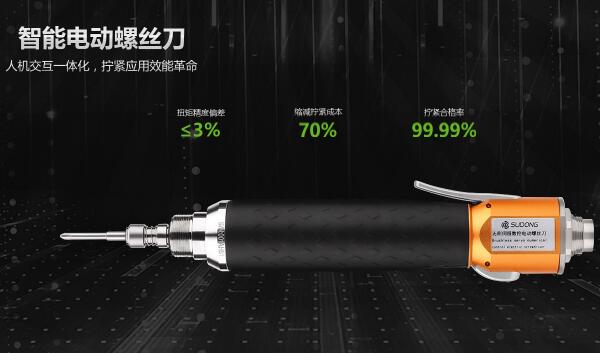

The high-speed servo electric screwdriver adopts an intelligent brushless servo electric screwdriver controller with a dedicated servo control algorithm. High output, fast response, high speed, small inertia, smooth rotation, and stable torque.

2、 Accuracy

1. The quick action brushless servo electric screwdriver is based on servo control technology, which can ensure that the torque accuracy of millions of tightening assemblies is controlled within a standard deviation of ≤ 3%.

2. Under normal working conditions, the quick acting brushless servo electric screwdriver can achieve a Cmk ≥ 1.67 (torque setting tolerance ± 10% in accordance with IS05393 and the 6 Sigma principle). The Cmk value of 1.67 means that there is only a 0.6 error rate per million screws, which is as high as 99.9994% pass rate.

3. The built-in current and angle measurement can achieve precise control and monitoring of the high-speed brushless servo electric screwdriver during various tightening processes, record all important tightening process parameters, and ensure the highest accuracy.

4. The quick action brushless servo electric screwdriver can achieve free programming of the tightening assembly process. Within the performance parameter range, it is possible to freely set and adjust torque, speed, waiting time, and rotation direction according to different tightening process requirements, achieving precise tightening.

3、 Cost

1. As mentioned above, the main reason why many manufacturers still use ordinary electric screwdrivers and pneumatic electric screwdrivers is cost. However, we must note that the service life of a regular electric screwdriver is significantly different from that of a servo electric screwdriver. From a long-term investment perspective, the monetary costs of the two are not far apart. However, in terms of production benefits, it can be said that the speed servo electric batch is superior to the ordinary electric batch.

2. The use of brushless servo motors significantly reduces operating costs, resulting in a long service life while ensuring robust power performance and torque output, making it an ideal CNC tightening assembly process choice for customers.

4. Data storage and statistics

The quick acting servo electric batch can achieve automatic statistical function, displaying the number of qualified, unqualified, and qualified rates on the main interface. At the same time, it can connect and store tightening records for 600 days, and the corresponding records can be exported through a computer. Provide scientific basis for quality tracking.

5. Easy to operate

1. The quick action brushless servo electric screwdriver adopts a brushless motor, combined with SD-PF5015 or SD-PF5030 controllers, to ensure the flexibility and reliability of the tightening process.

2. The high-precision and comprehensive monitoring function of the quick action brushless servo electric screwdriver can ensure the reliability of the tightening process to the greatest extent.

3. The quick action brushless servo electric screwdriver can achieve free programming of the tightening assembly process. Within the performance parameter range, it is possible to freely set and adjust torque, speed, waiting time, and rotation direction according to different tightening process requirements, achieving precise tightening.

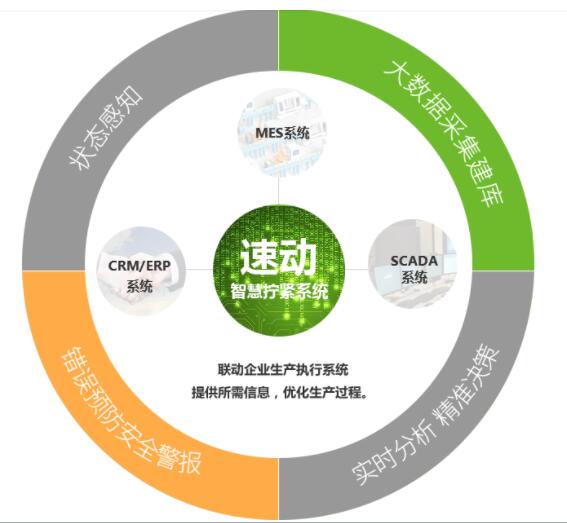

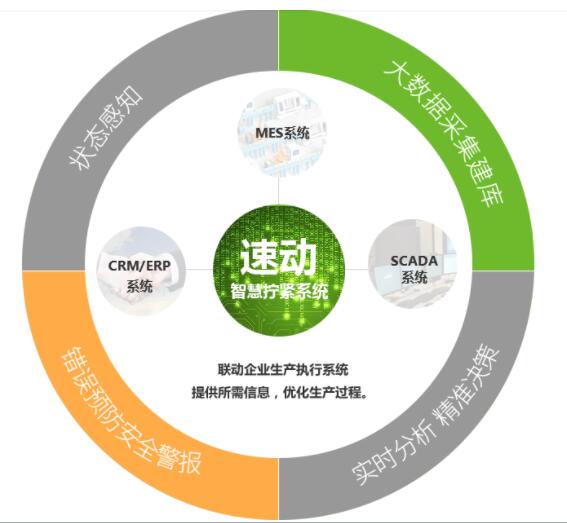

The difference between intelligent servo electric batch and ordinary electric batch mentioned above is shared here. The intelligent tightening system of quick action servo electric batch optimizes the tightening process, improves production efficiency, retrieves rework caused by common tightening faults such as floating locks, sliding teeth, and oblique strikes, and reduces unnecessary production costs.