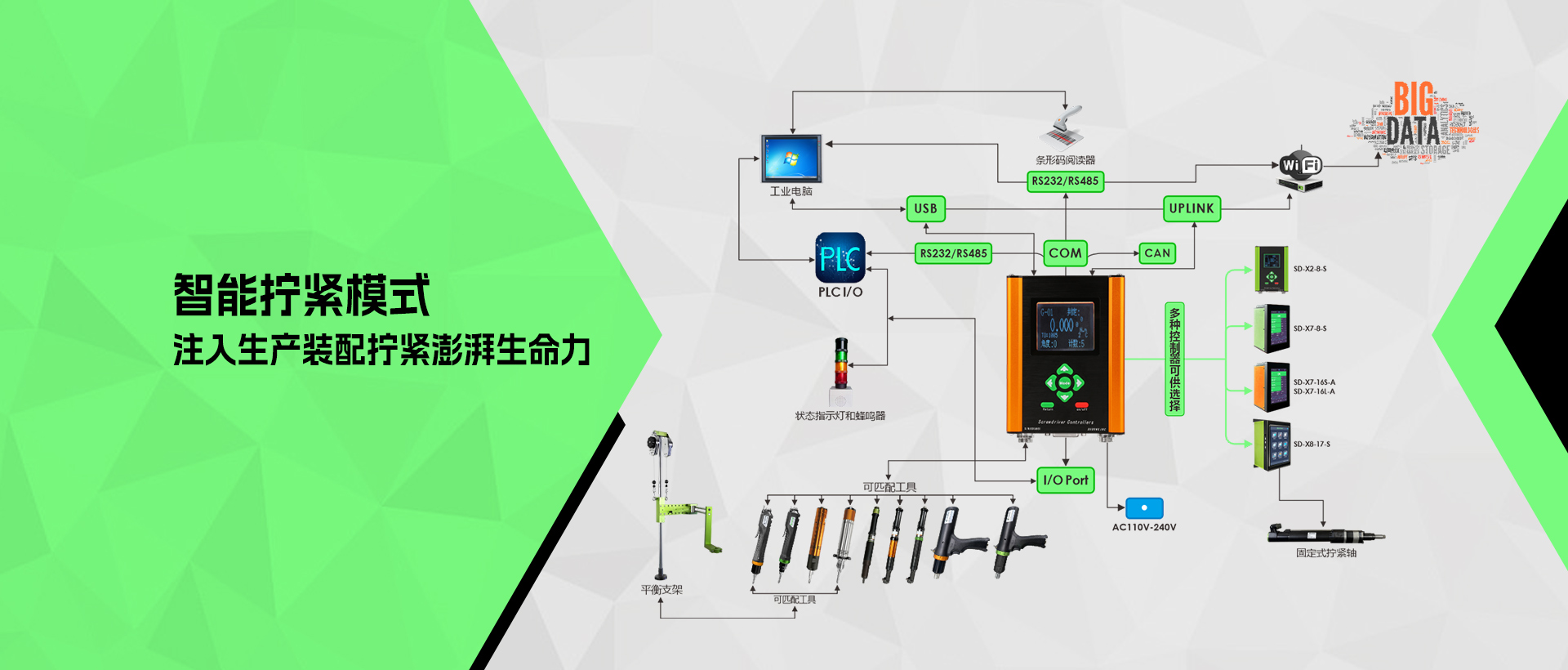

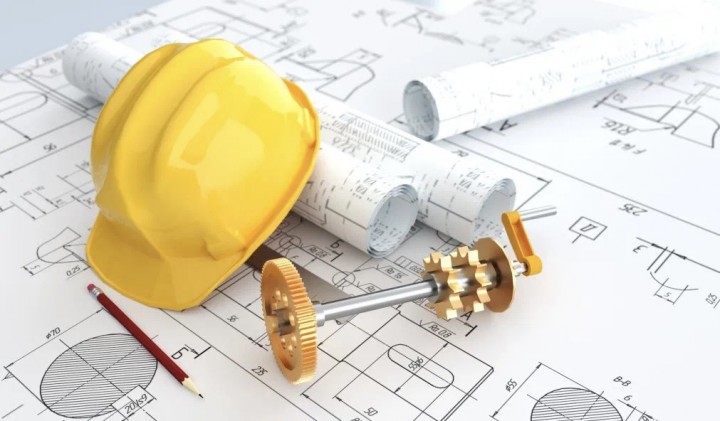

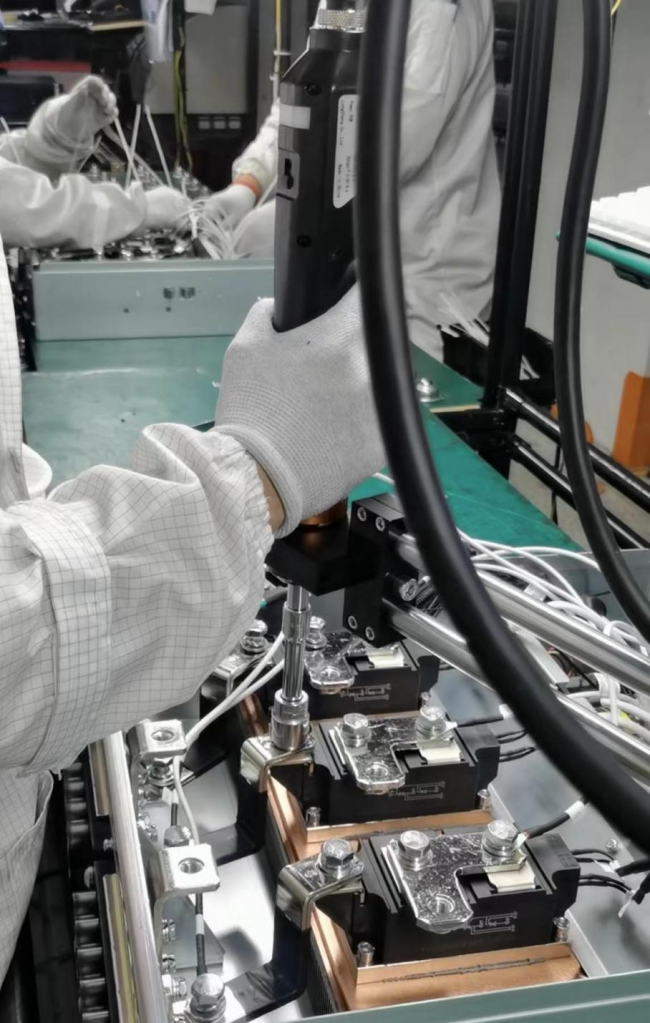

Intelligent Servo Transducer controlled Tightening Tool

The SUDONG brushless servo electric screwdriver is based on servo control technology, which can ensure that the torque accuracy of millions of tightening assemblies is controlled within the standard deviation of ± 3%.

More +