With the introduction and promotion of the concept of Industry 4.0, intelligent manufacturing has become an inevitable trend in the development of the manufacturing industry; With the increase of labor costs, reducing costs and increasing efficiency has become a necessary path for enterprise transformation; Flexibility, automation, and digitization of production have become common demands in modern manufacturing industries.

Especially with the continuous innovation of electronic product manufacturers, it is necessary to manufacture smaller, more precise, and more powerful digital products to meet consumer needs. This poses many new challenges to the existing assembly technology in the electronics industry, mainly reflected in the fact that electronic products require a large number of key components to connect, while their volume and weight are getting smaller and lighter, and materials are becoming more diverse. Therefore, smaller and shorter screws are needed for assembly. Therefore, intelligent assembly and data traceability have become necessary means to achieve change.

In order to meet the needs of market development and focus on digital tightening technology and digital assembly technology, we are committed to breaking through the underlying key technologies, mastering the core algorithms of digital tightening, and proposing the concepts of "intelligent tightening" and "digital tightening" to create high-precision, high-speed, and more intelligent products. We have innovatively launched industrial digital tightening systems, providing opportunities for microelectronics, large electronics, and other industries We provide professional solutions for intelligent manufacturing processes for customers in various fields such as automotive electronics.

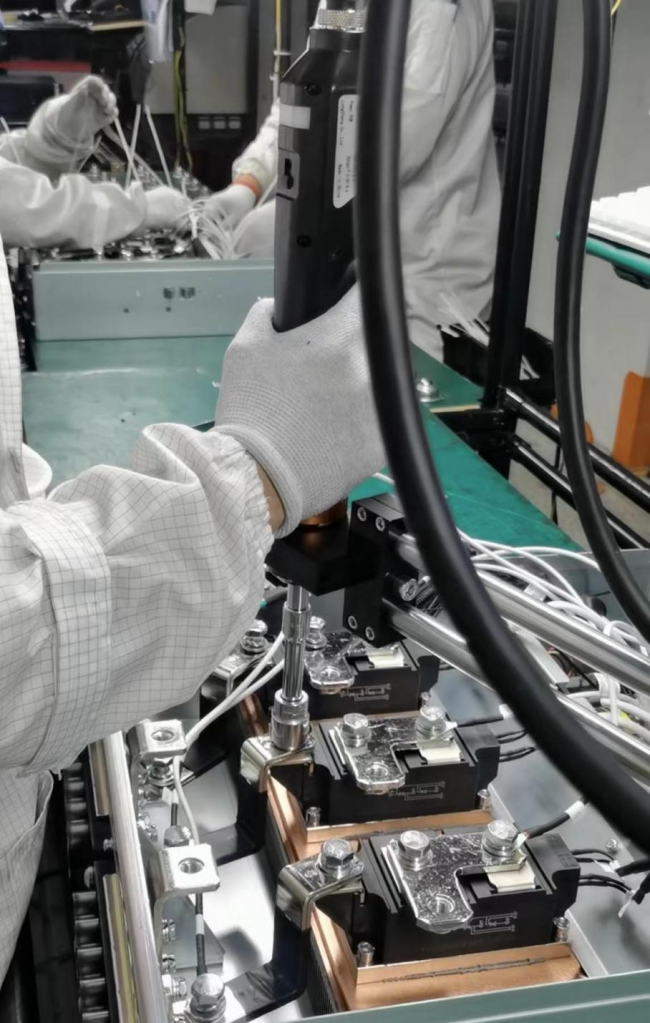

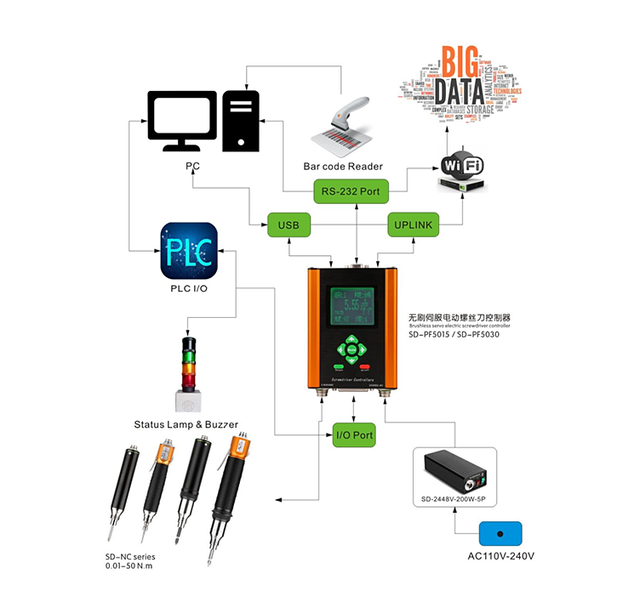

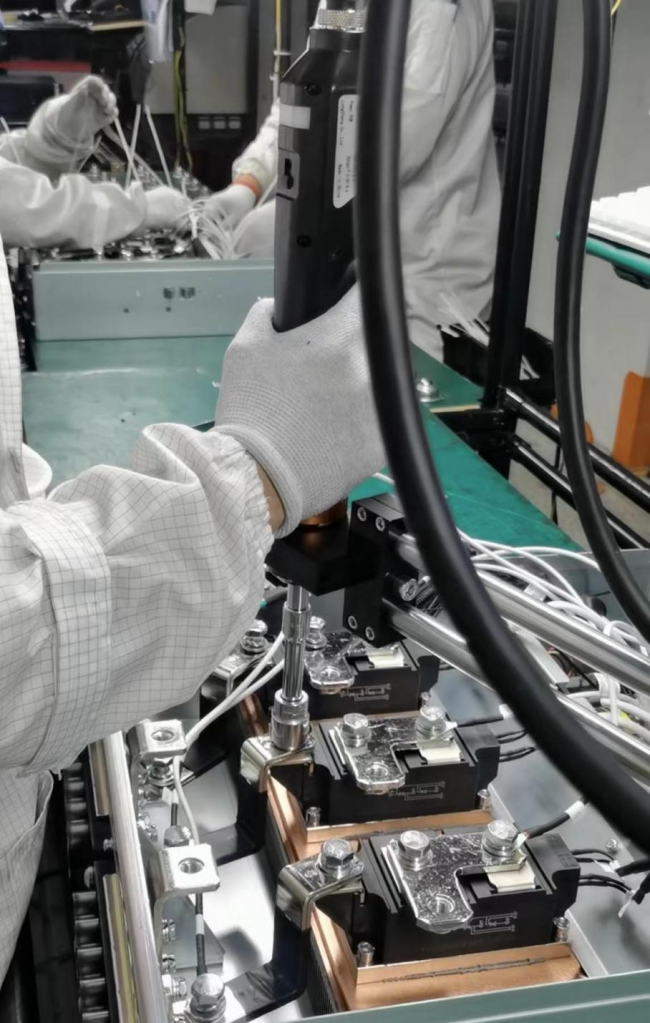

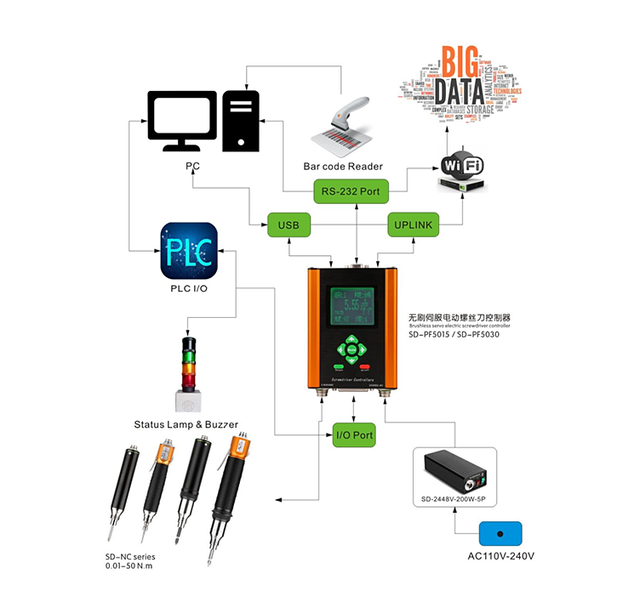

The industrial digital tightening system for quick action intelligent tightening, as a high-precision tightening system, can achieve visualization of tightening data, remote monitoring and management, coexistence of tightening modes, efficient production tightening, and comprehensive process detection. In practical operations, the system can provide flexible and diverse tightening schemes, and can connect various error prevention accessories to reduce tightening failures; It comes with various tightening error warnings, combined with efficient tightening schemes, which not only provide productivity but also significantly improve product yield; It can also optimize the tightening process, improve production efficiency, retrieve rework caused by common tightening faults such as floating locks, sliding teeth, and diagonal strikes, reduce unnecessary production costs, and achieve an overall torque accuracy deviation of ≤ 3%, reduce tightening costs by 70%, and achieve a tightening qualification rate of 99.99%; At the same time, the tightening results can be exported to a computer or factory database MES system to achieve local and cloud data storage and analysis functions, meeting the needs of the factory for controlling tightening operations and data storage and traceability. While achieving full data collection, existing data can also be statistically analyzed to further optimize existing production lines, efficiently and effectively promoting the digital and intelligent upgrading and development of production and assembly in the electronics industry.

With the transformation and upgrading of the electronic manufacturing industry from "manufacturing" to "intelligent manufacturing", the requirements for assembly quality and production efficiency are becoming increasingly stringent. Whether it is a relatively fixed production line for electronic products or a flexible production line with a wide variety of products, high-end intelligent tightening equipment is essential in the process of realizing intelligent and automated factory reform. Quick action intelligent tightening improves production efficiency and product quality through high-quality products, systematic solutions, professional technology and services, helping manufacturing industry customers stay ahead in Industry 4.0 and take every step of digital reform.