At the beginning of 2020, new infrastructure will welcome. New infrastructure refers to new infrastructure represented by 5G, artificial intelligence, industrial Internet and Internet of Things, which is essentially the infrastructure construction of information digitization. Digitization runs through every aspect of new infrastructure, and the tightening process, as an important part of industrial and manufacturing assembly processes, has shifted from traditional experience driven to data-driven. This is the trend of the new era of infrastructure.

Looking at the current situation of the tightening industry, the development level of China's electric screwdriver industry is still relatively backward compared to foreign countries. The technical content and accuracy of electric screwdrivers are low, and there are very few professional electric screwdrivers that can be applied in precision manufacturing and assembly processes. Faced with huge assembly needs, the relatively backward tightening level and tightening tools urgently need to be upgraded to intelligence and technology. The arrival of new infrastructure has sounded the horn of accelerating the technological and intelligent transformation of the industry.

Faced with the digitalization and intelligence requirements proposed by the market and "new infrastructure", as a leader in the industry, QuickAction Intelligent Tightening deeply understands that in order to change the current situation of the tightening industry and break the monopoly of foreign brands, it is necessary to break down technological barriers, continue independent research and innovation in technology, and achieve true "Made in China". Since its establishment in 2007, SUDONG has been focusing on the research and development, production, and sales of professional level intelligent servo electric screwdrivers and peripheral supporting products. Faced with the arrival of "new infrastructure", Quick Action has already made a comprehensive layout.

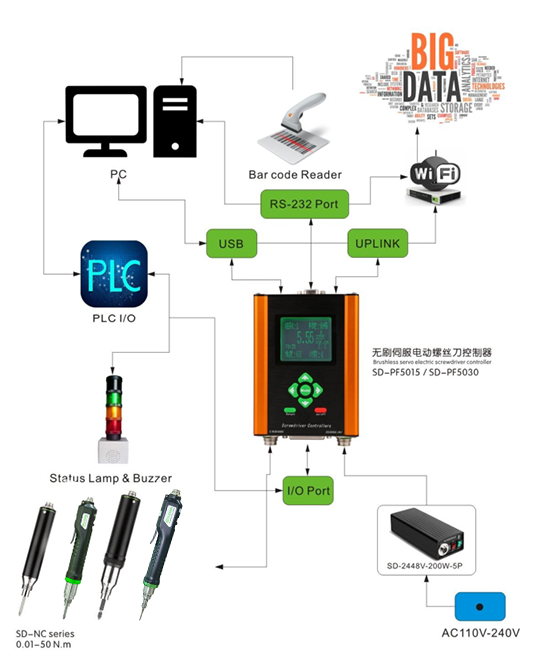

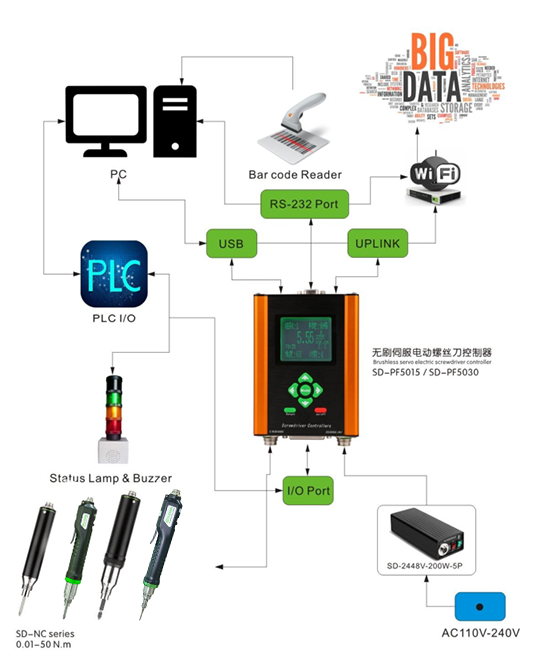

In terms of technical support, QuickAction has a group of industry-leading technical talents engaged in development, production and research, as well as an excellent management team. They have taken the lead in mastering the core technology of intelligent tightening, and continue to independently research and innovate tightening tools, providing customers with the most advanced tightening tools. In terms of product design, the quick acting intelligent servo electric screwdriver has advanced technology, excellent performance, and high cost-effectiveness. The ergonomically designed alloy body and external anti-static silicone grip are in line with ergonomics and have an excellent grip feeling; Equipped with high-performance servo motors and precision gearboxes, ensuring high-precision torque output. The torque accuracy of millions of tightening assemblies is accurately controlled within a standard deviation of ≤ 3%; The four steps of tooth insertion, screw insertion, initial tightening, and final tightening are simultaneously displayed in real-time on the data acquisition system, recording the entire tightening process data. It has a traceable intelligent data storage function. In terms of follow-up services, QuickAction provides the most comprehensive "one-stop matching" product service in the industry, as well as thoughtful after-sales repair services to ensure worry free use.

With the development of "new infrastructure" and the promotion of intelligent assembly concepts in the industry, under the guidance of application and demand orientation, adhering to technological innovation, integrating big data and artificial intelligence new technologies, and improving the level of technological intelligence in the tightening industry is currently the top priority of the industry. Sudong actively responds to market demand and always adheres to the business philosophy of "tightening is the core of all scientific research technologies" as the "new infrastructure" We provide professional and intelligent tightening products and services for various assembly processes!