Influenced by waves such as Industry 4.0 technology, artificial intelligence networking, and Made in China 2025, more and more manufacturing industries are shifting their development goals to industrial digitization construction. In this rapid digital transformation period, many manufacturing enterprises, especially contemporary traditional manufacturing and factories, urgently need to be restructured, and "intelligent digital capabilities" have become an important support for the transformation of many manufacturing enterprises. This also makes companies more willing to choose more expensive smart electric tools instead of traditional manual tools.

On the other hand, with the continuous upgrading of intelligent factories, the requirements for intelligent assembly and tightening processes are becoming increasingly strict. It is also required that tightening tools have data traceability technology, which can be used for the tightening assembly process of data traceability. After all, as the final step in most manufacturing processes, it is particularly important to improve the efficiency and accuracy of tightening and achieve scientific control. The updates and iterations of tightening technology have also injected new momentum into the manufacturing industry.

Based on years of experience in industrial tightening automation, "digitalization of tightening assembly" is a profound interpretation of the current trend of rapid digital tightening. As a global leader in industrial tightening automation, it is also "Industry 4.0" Leading practitioners and outstanding suppliers, SUDONG's scientific research technology is centered around digital tightening. Continuous scientific research innovation and product development have enabled SUDONG to stay ahead of industry development levels. It has constructively proposed the concepts of "digital tightening" and "intelligent tightening" in the industry, endowing traditional, low tech tightening tools with more technological connotations. The "Breakthrough" Sudong has truly achieved industry-leading technological innovation, not only breaking through technological barriers, but also breaking the monopoly of foreign brands.

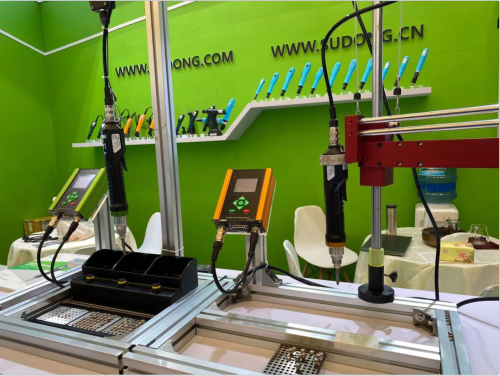

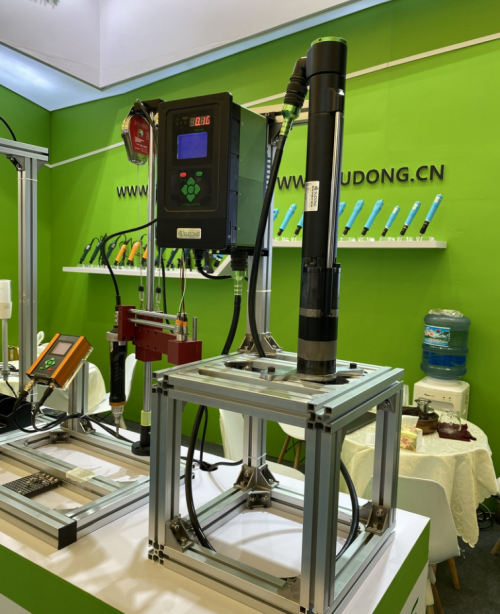

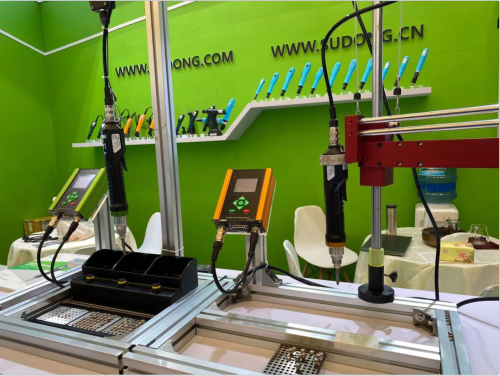

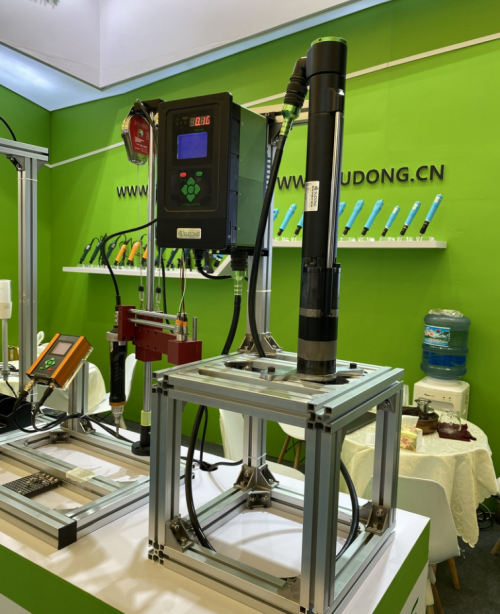

Furthermore, the core algorithm achievement with flexible digital traceability function developed through long-term research and development, combined with the rapid digital tightening, has been systematically tested and verified for many years. It has launched significantly advantageous carbon free electric screwdrivers, torque testers, and peripheral supporting products, providing customers in industries such as automobiles and components, new energy vehicles, and 3C electronic manufacturing with more unique features in the field of proprietary technology A digital tightening assembly service with good adaptability can achieve intelligent and digital tightening assembly actions in complex assembly environments.

Quick acting intelligent tightening: ushering in a new digital era of industrial tightening

Furthermore, in terms of screw tightening accuracy and torque, the quick acting SUDONG brushless intelligent electric screwdriver is based on servo control technology, which can ensure that the torque accuracy of millions of tightening assemblies is controlled within a standard deviation of ≤ 3%, achieving high-precision tightening; The intelligent brushless servo electric screwdriver controller it is equipped with can fully control the entire tightening process, greatly improving product quality and optimizing the tightening process. It can automatically identify tightening faults such as floating locks, slipping teeth, poor torque, and poor angle, greatly reducing torque problems that may occur during manual operation. The intelligent, precise, digital, and traceable brushless intelligent electric screwdriver is the best choice for tightening equipment that is most suitable for the current manufacturing industry.

Furthermore, in terms of digital traceability, the quick acting brushless servo electric screwdriver can achieve precise control and monitoring of the entire tightening process through built-in torque and angle sensors, and record all important tightening process parameters in real time. Its computer-based data acquisition system can store and generate curve tables for the entire tightening process data, Provide important information related to the tightening process, allowing people to visually see the specific tightening situation of components and provide feedback to improve tightening quality and efficiency.

In addition, the rapid digital intelligent tightening system can not only be applied to transformer installation, but also be promoted and applied to the production of control cable connectors, the production of main cable cars, the assembly of central pipe racks, and the assembly of central cable tank cars. It can be said that the application of the rapid digital intelligent tightening system will lead the improvement and innovation of assembly processes, promote the upgrading of intelligent and automated manufacturing in the company, improve product quality, and increase user satisfaction.

Finally, SUDONG will continue to conduct technological research and innovation in intelligent tightening technology in the future, creating a professional level brushless intelligent electric screwdriver that truly belongs to "China's creation". At the same time, it will also continue to set a benchmark in the industry, creating a new engine and model for the tightening industry!