Digital factories have become an important breakthrough for the transformation and upgrading of manufacturing enterprises, and the efficient utilization of resources and high-quality output of digital operations have become one of the essential capabilities for future manufacturing enterprises. And digital assembly has pushed the development of manufacturing to a new height. Assembling every screw also requires intelligent means to improve quality and efficiency.

Traditional screw tightening requires manual tightening, which cannot guarantee the controllability of tightening force and angle. This not only wastes time, but more importantly, it is prone to subjective errors during the tightening process, which can affect the quality of assembly. Quick action intelligent tightening is the first to master the core algorithm of digital tightening, and has constructively proposed the concepts of "intelligent tightening" and "digital tightening" in the industry. The emergence of industrial digital tightening systems has been particularly favored by manufacturing enterprises, because fast action intelligent tightening technology can help enterprises achieve the goal of digital assembly.

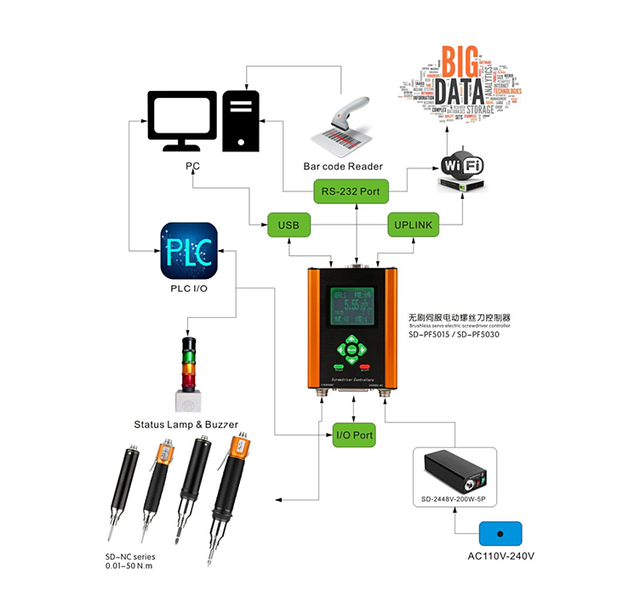

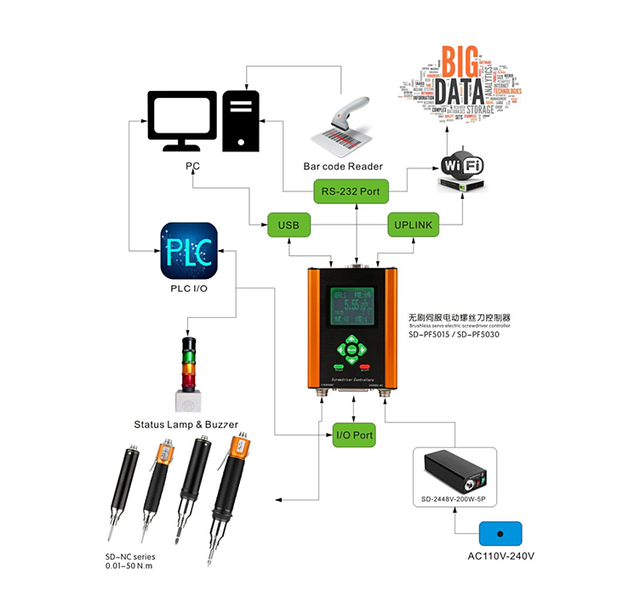

The industrial digital tightening system for quick action intelligent tightening is a high-precision tightening system that is easy to understand and use. It can achieve visualization of tightening data, remote monitoring and management, coexistence of tightening modes, efficient production tightening, and comprehensive process detection. It is a highly intelligent and high-precision digital tightening system. The industrial digital tightening system using rapid intelligent tightening can not only achieve automation of digital key assembly tasks, improve production efficiency, but also monitor and evaluate on-site process quality, analyze and upload results, which can help manufacturing enterprises achieve digital assembly, reduce costs, and improve product quality.

Digital assembly and intelligent digital tightening are a constantly expanding and improving process. Therefore, manufacturing enterprises need to pay attention to the continuous research and development of quick action intelligent tightening technology to obtain the latest technological progress and update technology according to specific production needs.

There are many application cases of industrial digital tightening systems with quick and intelligent tightening, which have important applications in automated assembly of manufacturing enterprises such as automobiles, home appliances, and electronic equipment, and have been widely recognized in the industry. At present, more and more manufacturing enterprises are realizing the importance of digital transformation and the future development trend of intelligent digital tightening. Therefore, manufacturing enterprises should strengthen their research and development investment in digital assembly and intelligent digital tightening systems, and promote the development and upgrading of technology in the industry.

As an enterprise focusing on digital tightening technology and digital assembly technology, Quick Action Intelligent Tightening Technology has launched a series of comprehensive services, such as technical support, after-sales service, etc., to meet the needs of manufacturing enterprises in the digital assembly process and make positive contributions to the development of the manufacturing industry. The rapid intelligent tightening technology has a professional R&D team and comprehensive after-sales service, combined with the development trend of digital factories, providing high-quality digital assembly services for manufacturing enterprises, and transmitting the information value of enterprise transformation and upgrading.

The new proposition of digital factories has opened up a broad avenue for digital assembly, and digital assembly will become the core force for the digital transformation and upgrading of manufacturing enterprises. The emergence and acceleration of the rapid intelligent tightening industrial digital tightening system have promoted the process of digital assembly, providing more stable and sustainable contributions for manufacturing enterprises.